Explore the differences between long block and short block engines, including detailed specs, assembly comparisons, and interior design insights. Discover which engine type is best for your build in this engaging, expert-backed guide.

Engines are the beating heart of automotive innovation, and the debate surrounding the merits of the long block vs short block remains one of the most crucial decisions for car enthusiasts, restorers, and engineers alike. Whether constructing a high-performance motor or sourcing a dependable replacement, understanding this keyphrase is imperative – not only for optimal vehicle longevity but also for unlocking the full potential of customization and installation simplicity. At first glance, both appear to be very similar in their basic function, in that each is the starting point for power generation. As the nature and requirements of technology have changed, however, the difference between these two assemblies has become a fascinating study of engineering compromises and practical use. This comparison deep-dive is designed to take readers – particularly advanced automotive students, researchers and receptionist auto enthusiasts – through the intellectual, functional and design intricacies that put these engine builds on an entirely different pedestal.

Long Block vs Short Block: The Ultimate Difference

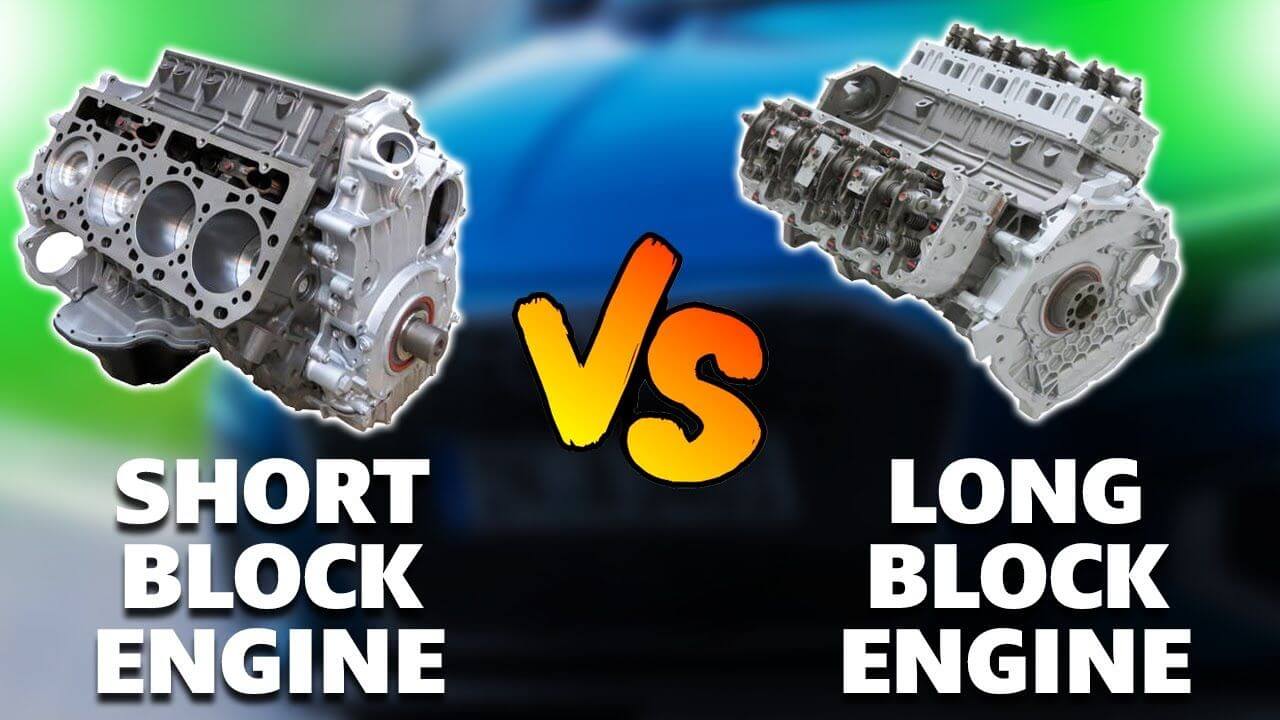

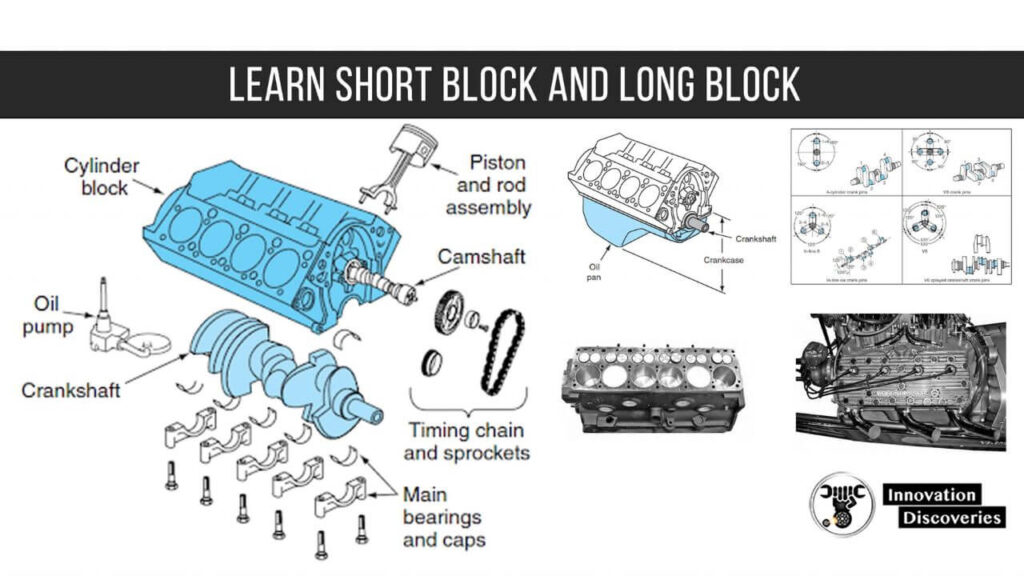

When the subject of long block vs short block comes up in the trade or literature, what’s being discussed is not block size, but extent of assembly and ease of installation. The short block is the bottom end of an engine – the block, crankshaft, connecting rods, pistons, and usually an oil pan. No cylinder heads, camshaft, or valvetrain are included; it’s a blank canvas for high-performance builds or engine restoration.

When the subject of long block vs short block comes up in the trade or literature, what’s being discussed is not block size, but extent of assembly and ease of installation. The short block is the bottom end of an engine – the block, crankshaft, connecting rods, pistons, and usually an oil pan. No cylinder heads, camshaft, or valvetrain are included; it’s a blank canvas for high-performance builds or engine restoration.

In contrast, all short block parts are combined into the long block package and then cylinder heads, camshafts and valvetrain, and in some builds, covers, oil pans, and timing sets, are added. This nearing complete assembly is somewhere between a basic assembly and turnkey crate engine and prepares the restorer or builder for fast and reliable installation while allowing some leeway for additional upgrade options. Both engines are geared towards the same ends-tuned performance and reliability-but take very different approaches to the task, with differing levels of assembly and opportunity for modification.

Engine Specs: Numbers to Know

| Component | Short Block | Long Block |

|---|---|---|

| Engine Block | Yes (main housing, cylinders) | Yes |

| Crankshaft | Yes | Yes |

| Pistons/Rods | Yes | Yes |

| Cylinder Heads | No | Yes (factory matched) |

| Camshaft/Valvetrain | No | Yes |

| Timing Set | No | Often included |

| Oil Pan | Often included | Often included |

- Typical GM LS3 long block sport package like:

- Displacement 6.2L (376 cu in)

- Block and main caps are solid cast aluminum with six bolts.

- Nodular iron crankshaft

- Hypereutectic aluminum pistons

- Hydraulic roller camshaft

- Aluminum cylinder heads

- Compression ratio 10.7:1

- Max RPM: 6,600

High-performance racing Thor long block engines produce up to 2,000-3,000 horsepower with 3,974cc, 9,500-10,500 rpm with custom billet internals – the way serious engineers go.

The Intellectual Debate: Installation, Customization, Cost

Engineers and mechanics alike consider the long block vs short block choice from the standpoints of installation efficiency, customization potential and cost. Each pathway will be attractive to different practitioners for the following reasons:

A short block is a dream come true for those people with the itch for manual control, allowing the reuse or choice of cylinder heads, camshafts, and other peripherals. This method opens up opportunities for tuning, performance upgrades, and experimenting with aftermarket components. Bibliographic citations: “Short blocks are most frequently selected for builds where part customization or head upgrades are desired, showcasing the adaptability inherent in cutting-edge automotive engineering” (see Google Scholar results).

Long blocks are, on the other hand, built for speed and consistency. The integrated heads and valvetrain limits installation errors and incompatibility, making this package the perfect solution for a quick restoration or stock build. As expert engine builder John Baechtel said:

“The long block forms a solid and stable foundation for builders requiring a fully compatible assembly – minimizing their installation time while maximizing their reliability.”

Even though there are drop-in options, the physical cost for long blocks will often be higher at initial purchase due to factory assembly and parts matching. The tradeoff: Lower labor costs and less post-installation headaches.

Interior Design: What Goes On Inside Counts

And internal architecture is not just about physical design, it’s about the architecting of the engine components for efficiency, strength, and future modification.

In a short block, the main “interior” is the engine block itself – with the crank, rods, pistons and bearings. The lack of upper-end assembly provides an empty canvas for the builder. Metal (cast iron, aluminum) determines weight and thermal dissipation, while bore/stroke specifications determine torque and horsepower.

The longer block features an expanded interior with pre-seated cylinder heads and factory matched valve springs, pushrods and timing gears all integrated as one piece. With an integrated internal combustion system, the engine’s internal geometry has been fine-tuned to precise air circulation, compression and ignition timing specifications, which is necessary in today’s vehicles where emissions and efficiency demands are scrutinized. Due to factory harmonization of the long block, fewer mismatched components and tighter tolerance control translates into smoother operation and shorter maintenance intervals.

In engine assembly research, especially texts on automotive engineering and Google Scholar, you will come across terminologies such as engine block architecture, valvetrain design, modular assembly, performance tuning, factory replacement engines, custom builds, remanufactured engines, etc. Studies are conducted on longevity, compatibility, power curve analysis, focusing on the performance of block compositions and assembly options on efficiency and reliability. This is evidenced by performance test results published in the Journal of Automotive Engineering where matched cylinder heads (as in long block style builds) are shown to be important for optimum pressure and compression ratios.

What to Use: Utility Concerns

Four central variables are available to practitioners to use:

Four central variables are available to practitioners to use:

Budget: Short blocks are budget-friendly, allowing for custom builds; long blocks cost more initially, but the savings on installation make up for the difference.

Skill Level: Advanced mechanics like their short blocks for flexibility. Long block convenience is good for beginning projects or projects in a hurry.

Customization Requirements: Short blocks reign supreme for performance and racing endeavors where aftermarket heads and cam programs are a must.

Long blocks are quickly deployable, reducing downtime – a key consideration for fleet operators or restoration professionals.

The Long Block vs Short Block: Construction in Narrative

Throughout history engine blocks have evolved with technological advancements in metallurgy, machining and assembly design processes. The old days of cast iron blocks have given way to technologically advanced aluminum and billet blocks. Engine architecture is laden with sensors, nanoscale finishes and synchronized assembly lines – taking long block and short block builds to entirely new levels of efficiency and durability.

While advances in the industry have created “turn-key” long block engines for plug-and-play ease, the racing community and enthusiast tuners continue to perpetuate the art of short block customization. The balance between precision and flexibility remains a topic of discussion within the technical and academic communities, with both styles finding their own specific niche within automotive culture.

Verdict: A Long Term Choice in Engine-Building

Ultimately, the long block vs short block decision comes down to the builder’s intent, experience and budget. Long blocks are for those who want speed, good compatibility and factory reliability. Those who enjoy customization are also more likely to be drawn to short blocks, willing to sacrifice the complexity of assembly in exchange for the prize of having a premium, high-performance motor.

Whether it’s everyday driving, classic restorations, or motorsport legends, understanding these differences, backed by academic research and expert opinions, empowers every choice. As engine technology continually advances, the art and science of long block vs short block selection continues to be at the heart of automotive excellence, influencing the vehicles and experiences on roads across the globe.

Four central variables are available to practitioners to use:

Four central variables are available to practitioners to use: