Learn about the most important clutch function in automatic transmissions. Learn how this key component functions and why it provides for smooth shifting and vehicle performance.

When referring to the clutch in an automatic car, most people think there is no clutch, because there is no clutch pedal. However, the clutch in automatic transmissions has a very important role in the background that is essential to smooth gear shifting and power delivery. This blog will explore the clutch in automatic systems in detail, discussing how it works, the various forms it can take and why it is indispensable to modern automatic vehicles. Through this wide-ranging exploration readers will gain a clear understanding of the function, design, and importance of the clutch in automatic cars – allowing them to understand the sophistication of these systems beyond the simplification of not having to operate the clutch pedal.

Understanding the Clutch in Automatic Transmissions

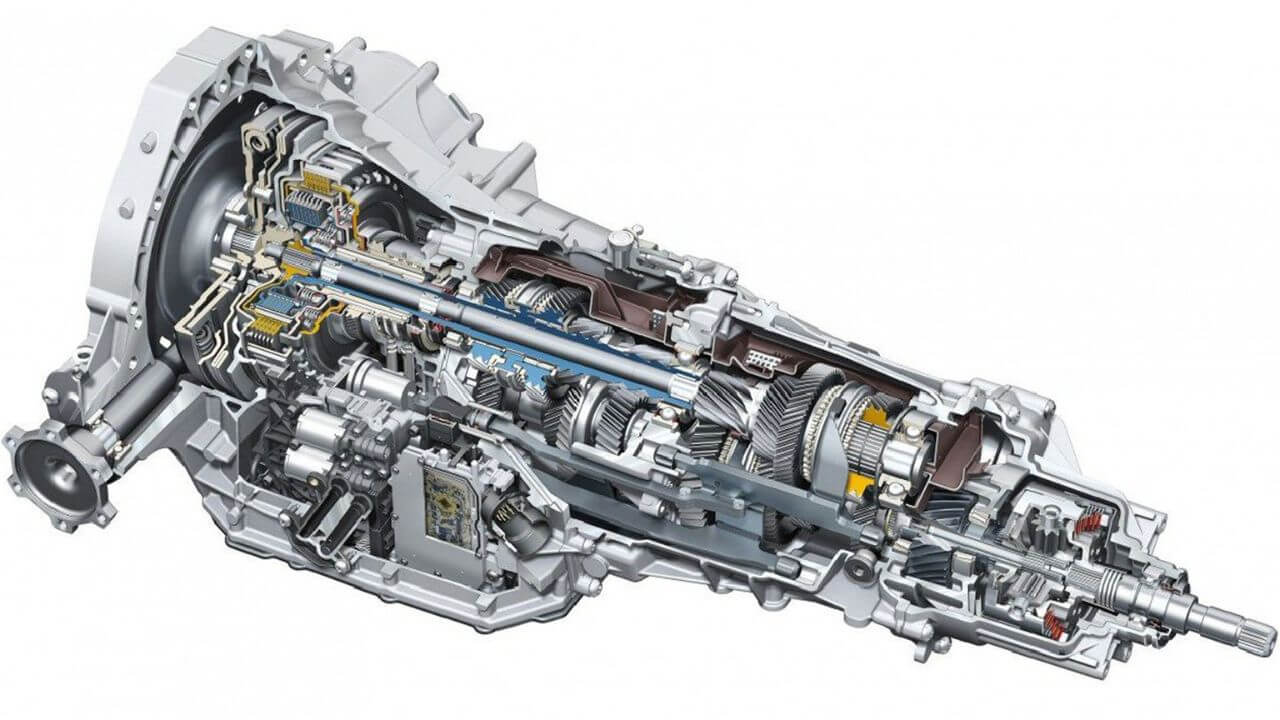

In an automatic transmission, the clutch is used to send power from a transmission’s engine to its planetary gear sets. These clutches slip in and out in exact coordination to shift the gears without the driver input and make the gear shift very smooth. This automatic management of engagement helps to reduce the possibility of gear shock and wear due to improper clutch use.

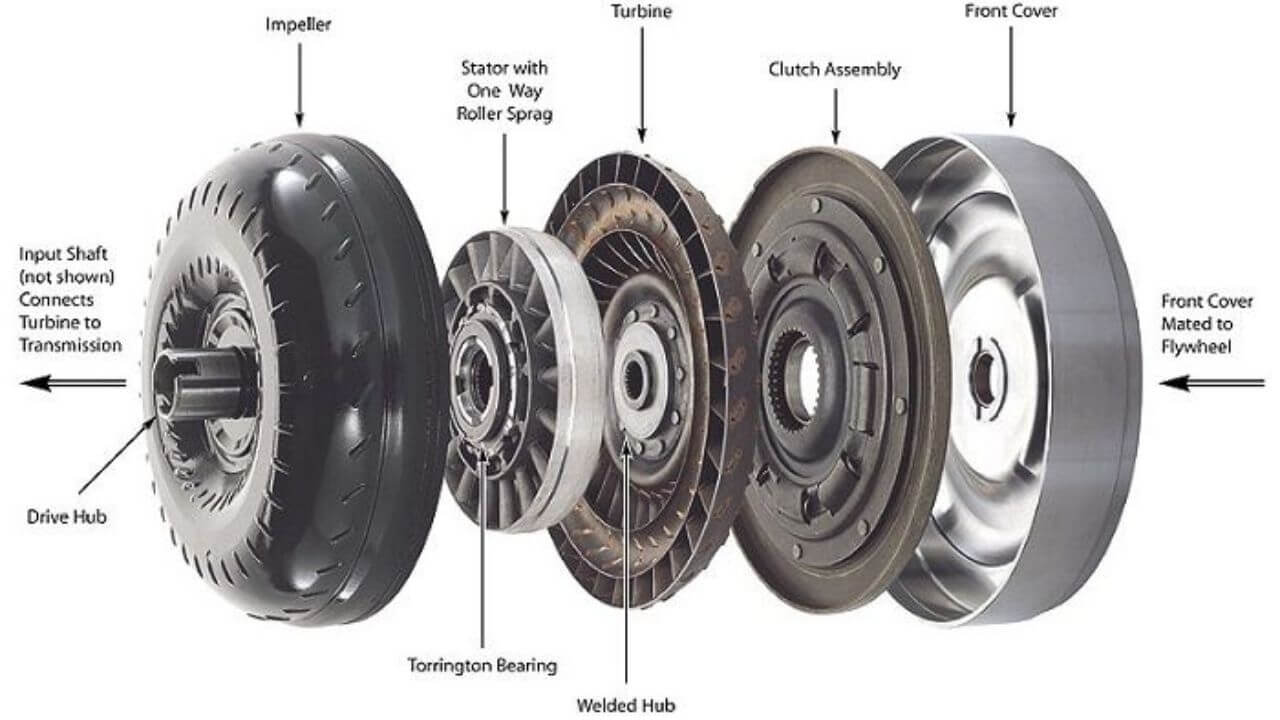

Most automatic cars use a torque converter (a fluid coupling device) as the main means of transmitting torque from the engine to the transmission while allowing for slight slippage to provide smoothness. Modern automatic systems may also make use of clutch packs which are sets of friction discs, which perform the same function as a manual clutch, however the clutch is automatically controlled.

How Does Clutch in Automatic Transmissions Work?

The process can be divided into phases:

- Fill Phase: To start, hydraulic fluid fills the clutch chamber in preparation for engaging the clutch plates.

- Torque Phase: The torque is switched from the outgoing clutch to the incoming clutch. Proper control in this phase ensures the absence of jerks or delays.

- Inertia Phase: The speed of the transmission gets synchronized with the engine speed for the smooth change of gears.

This clutch-to-clutch shifting is strictly regulated by the transmission control unit (TCU), which uses sensors, solenoids and electronic algorithms to optimize pressure application. The goal is to avoid clutch slippage or harsh engagement, which can affect comfort and long-term transmission health.

Kinds of Clutches in Automatic Transmissions

Automatic cars can use different types of clutch to operate depending on the type of transmission system:

- Torque Converter Clutch (TCC): Found in most traditional automatics, this clutch locks the torque converter at higher speeds to make a direct mechanical connection between the engine and transmission, increasing gas mileage by reducing engine slippage.

- Clutch Packs: These are made up of multiple friction discs which are squeezed together hydraulically in order to engage gears. They are used in automatic transmissions with planetary gears, and also in dual clutch transmissions (DCT), where two separate clutches are used, for odd and even gears, to improve shift speed and smoothness of transmission.

- Wet Clutches: Immersed in transmission fluid, these clutches offer a cooler and more even engagement and are therefore often used with automatic transmissions.

- Dry Clutches: Less common in automatics, you will find dry clutches in some automated manual transmissions when lubrication is less of an issue.

Why The Clutch In Automatic Transmissions Are Vital

The clutch system is important because it controls the flow of power between the engine and the wheels during gear shifts, making sure:

- Smooth Driving Experience: Without the coordination of the clutch, shifting gears between gears would result in jolts or interruptions in power.

- Transmission Durability: The clutch slipping and engagement will protect the components of the transmission from excessive wear.

- Fuel Efficiency: The lock-up clutch used on torque converters reduces energy losses.

- Driver Convenience: Automatic clutch operation eliminates the need for manual pedal control, making driving easier and more accessible.

As DI Poporetskiy, an expert on transmission durability, states

“The life of the automatic transmission is determined to a great extent by the durability of the friction disks, which are a part of the clutch system.” Proper clutch management has a direct affect on longevity and shift quality”.

Common Automatic Clutch Signs and Maintenance

Even though automatic clutches operate differently from manual clutches, they still need attention:

- Signs of Wear: Sign of wear are delayed or harsh shifting, slipping gears, unusual noises in gear changes.

- Maintenance: Regular transmission fluid checks and changes are important because the condition of the transmission fluid affects clutch performance and lifespan.

- Longevity: Automatic transmission clutches last a long time (30,000 to 100,000 miles) depending on driving habits and maintenance.

Proper Care Extends Clutch and Overall Transmission Life Avoiding costly repairs.

Exploring Recent Developments in Clutch Control

Recent academic research and research focuses on the use of software adaptive control strategies to improve clutch operation in automatic transmissions. These algorithms optimize the hydraulic pressure during the phases of clutch engagement, in order to reduce the wear and to improve the smoothness of the passage, compensating the manufacturing tolerances and the phenomena of ageing in the transmission systems.

Similarly, inroads are being made in the application of deep reinforcement learning and electronic control units to refine gearshift controllers for clutch actuation, with the promise of more efficient and reliable transmissions in future vehicles.

Clutch in Automatic Transmission Vs. Manual Clutch

Unlike manual transmissions in which the driver must operate a clutch pedal manually to disconnect the engine from the drivetrain when shifting gears, the clutch in automatic transmissions works seamlessly without any driver interaction. This is made possible by hydraulic or electronic actuation of clutch packs or torque converters controlled by on-board transmission management systems.

The absence of a clutch pedal does not mean that there is no clutch mechanism Instead, it represents an automation of clutch operations for better ease of use and less human error. This transition has been critical in the ability to make driving accessible to millions of people around the world that focuses on the convenience aspect without losing any mechanical efficiency.

The Future of Automatic Transmission Clutch Technology

With the auto industry’s focus on electrification and intelligent cars, the development of clutch for automatic transmissions is changing. Innovations center around reducing energy losses, enhancing shift responsiveness, and increasing the life of components. Hybrid electric vehicles (HEVs) and electric vehicles (EVs) represent new challenges and opportunities for clutch design, especially in the case of multi-mode transmissions.

Advanced materials, improved lubrication fluids, and artificial intelligence (AI)-driven control strategies are likely to continue to shape the design of clutches, ensuring that even as vehicle technology changes, the clutch continues to be a cornerstone for optimal power management and driving comfort.

Results: The Silent Power of the Clutch in Automatic Cars

While too often overlooked by drivers unaccustomed to shifting gears manually, in automatic transmissions the clutch is an ingenious and indispensable device. It coordinates the smooth functioning of power by allowing gear shifts to happen smoothly and efficiently without driver intervention. From the hydraulic clutch packs to the lock-up clutch in torque converters, these mechanisms operate silently but vitally to provide comfort, longevity and performance for automatic vehicles.

Understanding the role of the clutch helps to deepen your appreciation for the engineering complexity that goes into automatic transmissions and demonstrates the importance of regular maintenance to ensure that the clutch and the transmission remain healthy.

In essence, the automatic transmission clutch is the unsung hero that facilitates seamless driving, representing sophisticated technology that is designed to boost modern-day mobility.